- 您现在的位置:买卖IC网 > Sheet目录113 > SMLK28WBJCW1 (Rohm Semiconductor)LED WHITE 21LM 90MA 8000K 4520

www.rohm.com�

� ? 2014 ROHM Co., Ltd. All rights reserved.�

� Data Sheet�

� SMLK1 / SMLK2 series�

� lAttention Points In Handling�

� This product was developed as a surface mount LED especially suitable for reflow soldering.�

� Please take care of following points when using this device.�

� 1.DESIGNING OF PCB�

� As for a recommendable solder pattern, Please refer to Fig-1.④�

� The size and direction of the pad pattern depend on the condition of the PCB.�

� so, please investigate about the adjustment thoroughly before designing.�

� ( n.b) �

� Performance/characteristics of devise shall considerably differ �

� depending on mounting conditions. That is to say, the optimized①�

� ②�

� 0.4�

� heat-radiation mounting will make best use of device’s performance.1.1�

� Thus, it in recommended to design the land pattern with use of�

� Cu for a great deal of heat-radiation as well as the use of metal mounting board. ) �

� 2.SOLDERING�

� LED products do not contain reinforcement�

� materials such as glass fillers.�

� Therefore, thermal stress by soldering greatly�

� influence its reliability.�

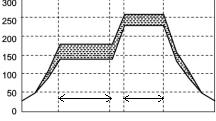

� The temperature conditions for reflow soldering�

� should therefore be set up according to the �

� characteristic of this product. (See Fig-2)�

� Number of reflow process shall be max 2 times �

� and these processes shall be performed in a row.�

� Cooling process to normal temperature shall be required�

� between first and second soldering process.�

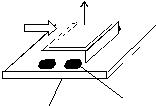

� 3.USE OF AUTOMATIC MOUNTING MACHINE�

� As for this product, the silicone resin is used as encapsulate material and the sealing part on top of LED is soft.�

� Therefore, please make sure not to apply the pressure upon it, as it might influence reliability.�

� Moreover, please use the adsorption nozzle when you use the automatic mounting machine so as not to apply�

� the force directly to this top sealing part.�

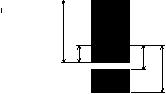

� 4.HANDLING AFTER MOUNTING�

� As shown right drawing, in case outside force is given�

� to the device, stress is concentrated to the jointed part�

� between mold resin and substrate.�

� Therefore there is a possibility to breath the device or PCB.�

� Careful handing is needed as ROHM cannot guarantee the falling�

� of the device by outside force after mounting.�

� Min.1 min③ ④Max. 40sec�

� Max.260oC, Within 10sec�

� 140 to 180oC�

� 230�

� to 260oC�

� (Fig-2)�

� (Fig-1)�

� Soldering �

� PCB�

� Emitting Direction�

� Outside Force�

� 2.7�

� 4�

� 3.25�

� 4.5�

� 1.54�

� 0.3�

� 0.6�

� 0.85�

� 3.5�

� 0.2�

� 1.5�

� 2�

� 0.9�

� 3.65�

� 1.4�

� 2.75�

� 参考ランドパターン�

� ③ ④�

� anode�

� ① ②�

� cathode�

� ③�

� ④ ③�

� ① ②�

� ① ②�

� 1.74�

� 8/9�

� 2014.01 - Rev.B�

�  �

�

� �  �

�

� �  �

�

� �  �

�

� �  �

�

� �  �

�

� �  �

�

� 发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

SMMBD7000LT3G

DIODE SWITCH DUAL 100V SOT-23

SMMBD701LT1G

DIODE SCHOTTKY 200MW 70V SOT23

SMS7621-096

DIODE SCHOTTKY SILICON 2V 0201

SR20200-G

DIODE SCHOTTKY 20A 200V ITO220AB

SS10P3CLHM3/86A

DIODE SCHOTTKY 10A 30V SMPC

SS10P4CHM3/86A

DIODE SCHOTTKY 10A 40V SMPC

SS12P4CHM3/86A

DIODE SCHOTTKY 12A 40V SMPC

SS6P4CHM3/86A

DIODE SCHOTTKY 6A 40V SMPC

相关代理商/技术参数

SMLK34

制造商:ROHM 制造商全称:Rohm 功能描述:High heat radiation package from ROHM original flat frame structure

SMLK34_11

制造商:ROHM 制造商全称:Rohm 功能描述:High heat radiation package from ROHM original flat frame

SMLK34WBEAW

制造商:ROHM 制造商全称:Rohm 功能描述:High heat radiation package from ROHM original flat frame structure

SMLK34WBEAW1

功能描述:LED WHITE 10LM 60MA 5000K 4520 RoHS:是 类别:光电元件 >> LED - SML 标准包装:500 系列:Screenmaster® 颜色:琥珀 Millicandela 等级:2260mcd 正向电压:2.1V 电流 - 测试:20mA 波长 - 主:590nm 波长 - 峰值:- 视角:- 透镜类型:散射,有色 透镜样式/尺寸:圆顶椭圆,5.1mm x 3.7mm 封装/外壳:径向 尺寸/尺寸:- 高度:7.00mm 安装类型:通孔 包装:散装 在特定电流下的光通量 - 测试:-

SMLK34WBEAW11F

制造商:ROHM 制造商全称:Rohm 功能描述:High heat radiation package from ROHM original flat frame structure

SMLK34WBEAW14

制造商:ROHM Semiconductor 功能描述:

SMLK34WBEBW

制造商:ROHM 制造商全称:Rohm 功能描述:High heat radiation package from ROHM original flat frame structure

SMLK34WBEBW1

功能描述:LED WHITE 10LM 60MA 5000K 4520 RoHS:是 类别:光电元件 >> LED - SML 标准包装:500 系列:Screenmaster® 颜色:琥珀 Millicandela 等级:2260mcd 正向电压:2.1V 电流 - 测试:20mA 波长 - 主:590nm 波长 - 峰值:- 视角:- 透镜类型:散射,有色 透镜样式/尺寸:圆顶椭圆,5.1mm x 3.7mm 封装/外壳:径向 尺寸/尺寸:- 高度:7.00mm 安装类型:通孔 包装:散装 在特定电流下的光通量 - 测试:-